A reduced version of this article has been presented

in the Management Innovation Newsletter no. 28

Angelo Bonomi

Senior Research Associate

IRCRES – CNR

abonomi@bluewin.ch

INTRODUCTION

The Research Institute on Sustainable Economic Growth (IRCRES) of the Italian National Research Council (CNR) is carrying out a technological study on Industry 4.0 in relation to opportunities and problems about its implementation in SMEs and industrial districts. Although this study is far to be concluded, we present here some preliminary considerations for discussion. Industry 4.0 is now the object of various and numerous studies but the technological approach used by IRCRES in this study is original, and it does not concern detailed descriptions of technologies involved in Industry 4.0 and their use, but it concerns the study of technology dynamics and evolutions that are accompanying such industrial revolution and problems that should be faced. The study is based on a certain number of previous works, published on the IRCRES site www.ircres.cnr.it, and concerning: a study on the demand and offer of R&D for SMEs (Technical Report CERIS N. 46, October 2013), a series of working papers concerning: bridging organizations between university and industry (WP Ceris 15/2014), a model of technology and technology innovation (WP IRCRES 3/2016), a model of the R&D process (WP IRCRES 2/2017), a mathematical simulation of the R&D process (WP IRCRES 6/2017), and a recent publication in 2018 on Quaderni IRCRES Vol. 3 N. 1 of a study on territorial innovative systems. From the point of view of these studies technology is seen as a structure composed by technological operations, and technology innovation as a change in this structure. R&D is seen as an organizing activity of fluxes of capitals and knowledge, generating both new technologies and a new general knowledge boosting new R&D projects because of the autocatalytic nature of R&D. In a first part of the study we describe some technological dynamics and enabling technologies characterizing Industry 4.0, and in a second part the innovation channels for Industry 4.0 constituted by firms producing software and hardware, technical consulting firms, universities and public and private research laboratories, and start-up, and finally we present some considerations about Industry 4.0 and SMEs and conclusions.

THE TECHNOLOGIES OF INDUSTRY 4.0

Technologies involved in Industry 4.0 are generally called enabling technologies. The formation of the technological complex characterizing manufacturing in Industry 4.0 will be the result of the confluence of such technologies. The transformation times and precise paces characterizing such revolution are for the moment unknown, but prosperity of countries will probably depend on the state of advancement of such revolution. As the full implementation of Industry 4.0 will probably take a long time, in discussing the possible evolution of enabling technology it is necessary to take account also of evolution of the great fields of research in which they are originated, such as nanotechnologies, biotechnologies, digitalizing technologies and artificial intelligence, taking account also of new potential applications that are now only at the initial stage. That means to consider: for nanotechnologies nanostructured materials and surfaces, for biotechnologies synthetic biology and biological computers, for digitalizing technologies new design for miniaturizing circuits and quantum computing, and for artificial intelligence artificial neural networks. This last technology is considered the core technology of Industry 4.0 determining possibilities and limits of this revolution. Before discussing the various enabling technologies, it is useful to present a certain number of process dynamics that characterize the evolution of such technologies and difficulties in their implementation. Such processes are: the ramification of technologies, the Red Queen Regime, the intranality effects and the speed of technological changes.

Ramification of technologies

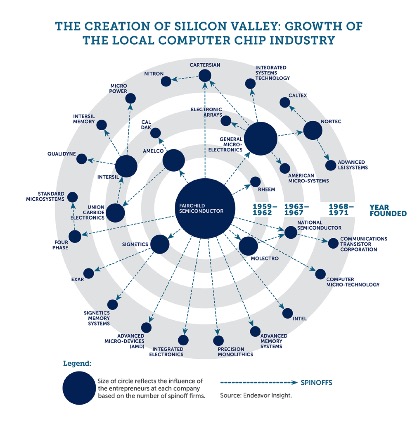

Typically, a starting radical innovation may lead to generation of numerous other technologies, normally with a lower radical character, leading to a large diversification of applications. Considering a technology as a point, it may be linked to further points that represent an improvement or diversification of the technology, the whole assuming the form of a developed ramification. An indirect representation of such ramifications has been observed considering for example the hundreds of patents on computerized tomography from the initial patent in 1973 to 2004. Or differently, the 35 start-up generated from Fairchild Semiconductors between 1959 and 1971 that assume also a ramified form. In Industry 4.0 we have the case of 3D printing, derived by an ink jet printing technology, first applied at low temperature with plastic materials, and further developed for medium and high temperature and applied also to metals and ceramics. It should be noted that in the initial and intermediate part of a ramification, innovations result from research and R&D laboratories, but in the terminal part innovations are mostly made during the industrialization phase and by learning by doing, making important also intermediate technical education for extension and diversification of a technology.

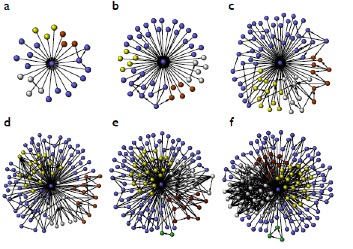

Technology ramification: evolution of computerized tomography patents, from 1975 to 2005, represented topologically by the various points. Each connection represents a citation of a previous patent indicating an improvement or a diversification of the patent. (Valverde S. Solé R. Bedau M. Packard N.2007, Topology and Evolution of Technology Innovation Networks, Phys. Int. Rev. E 76, 032767)

The Red Queen Regime

The Red Queen regime consists in a situation existing typically in industrial districts in which technologies are continually innovated incrementally but with only a limited economic development. That is due to the fact that all firms have about the same competences, and a technological advantage of an innovation of a firm is easily eliminated by a similar one by a concurrent firm with the same competences. The Red Queen regime was introduced for the first time to explain genetic competition. The Red Queen is a character of Lewis Carroll’s “Alice’s Adventures in Wonderland” that tells to Alice “In this place it takes all the running you can do, to keep in the same place”. Such regime is destroyed by appearance of radical innovations. Implementing of Industry 4.0 in industrial districts may be difficult because of tendency to remain in such regime and be reluctant in introducing radical innovations.

Intranality of technology

The model of technology defines as intranality the fact that an optimization of efficiency of an operation may affect the efficiency of other operations, and optimization of a technology necessitates a tuning among the various operations efficiency. Such effect exists also when the structure of a technology is changed, and substitution of an operation may affect other operations that should be tuned to improve the technology efficiency associated with the innovation. When all technological operations are carried in the same firm, intranality effects can be easily controlled. That it is not the case of industrial districts in which often some operations are subcontracted to specialized firms that have many other clients. These subcontractors may not be interested to introduce modifications to make valid the introduction of a new technology. In such case cooperation of producers and subcontracting firms in the development of an innovation is important to avoid this effect.

Technology ramification: generated start-up from 1959 to 1971. Each arrow represents a direct or indirect spin off from Fairchild Semiconductors. (Morris R. The First Trillion-Dollar Startup, Endeavour Insight Monthly Newsletter, Jul. 26, 2014)

Innovation speed

The velocity of appearance of innovations may influence the management of projects making obsolete technologies planned for the project. Such effect was observed for the first time in firms of New York’s Silicon Alley offering Internet services to companies. Solutions adopted were availability of diversified competences and flexibility in project management. Such problem may affect technological consulting firms offering project for implementation of Industry 4.0.

The enabling technologies of Industry 4.0 normally cited are: collaborative robotics, augmented reality, additive manufacturing, digital manufacturing,digital twin, big data, cloud computing,internet of things (IoT) and cybersecurity. The various enabling technologies may be classified following the type of influence they have on the manufacturing operations:

Specific technologies for operations

These are: collaborative robotic that is an evolution of robots able to interact with human operators, and augmented reality that allows the operator to have much more direct information about the production process. Another enabling technology directly linked with operations is additive manufacturing.

Technologies connecting and coordinating the operations

This is the field of technologies of digital manufacturing composed by hardware, sensors and software for management. There are many technologies following the level of connection or coordination such as PLC, SCADA, MES, ERP, etc.

Technologies of simulation

This is the case of digital twin that represents a technology making possible a digital virtual representation of an object or a process of production. It may be applied in the development of processes or materials, in increasing the predictive life of mechanical parts and optimization of manufacturing processes.

Technologies for general applications

These technologies include: big data, a technology able to record great quantities of data generally in the cloud but it may be done also internally to a firm, cloud computing offering updated algorithms in the cloud for calculations necessary in use of enabling technologies. Sometimes there is a too long time of access or calculation in the cloud in respect to the exigence of the firm, and there are also internal technologies avoiding these problems as fog computing. Finally, there is the technology of cybersecurity protecting either external or internal communications of the firm.

Technologies for the product

These technologies called Internet of Things (IoT) consist in introducing in the product sensors, memory, computing, GPS, transmission systems that connect the product with the producers or other products. In this way it is possible to have information useful to improve production, commercialization and elaboration of new products. It is possible also to make remote maintenance and communication among products to improve their functioning.

The most important difficulty in implementing enabling technologies in Industry 4.0 concerns the need to integrate informatic and communications technologies (ICT) with operating technologies (OT) of manufacturing, fact that it is much more complex that simply adding ICT technologies such as Internet sites or similar ITC technologies to firms. Another difficulty that may appear in implementing Industry 4.0 in consecutive phases is the compatibility of standards and protocols between new technologies and those already existing in the firm.

INNOVATIVE CHANNELS FOR INDUSTRY 4.0

Implementation of Industry 4.0 in a manufacture is essentially based on an offer of technologies and innovation to firms. However, this offer cannot be considered a simple transfer of technology from research to industry, but it is much more complex and achieved through a complex ecosystem constituted by hardware and software producers, technological consulting firms, start-up, universities and public or private research laboratories. Such ecosystem is polarized from one side by the gigantic companies making software, operative systems and other services such as Microsoft, Google. Apple, etc. and, on the other side by the major companies producing electronic components for hardware such as Intel. In the ecosystem we have big companies previously involved in hardware but developing also software such as Bosch, Siemens, GE, etc. and offering technologies and innovations through industrial platforms. The ecosystem includes also technological consulting firms, research laboratories and start up. Each of these actors merits a description on possibilities and limits of their innovative offer.

Industrial platforms and the big firms in hardware and software

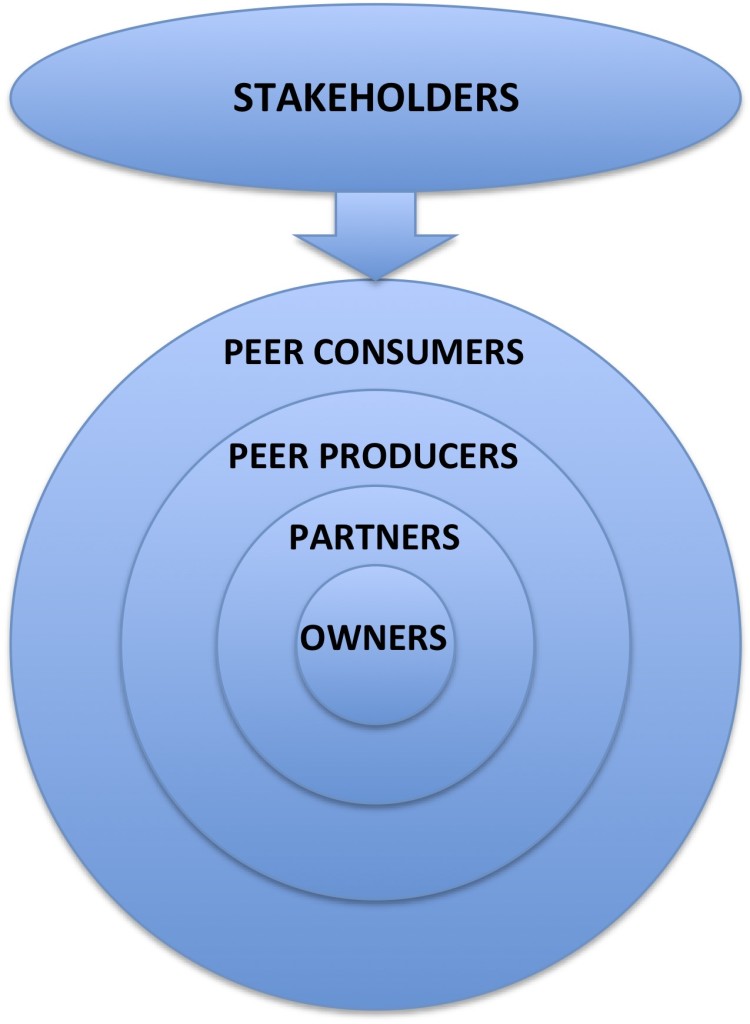

The study has put in evidence that major firms in hardware and software offer technologies for the implementation of Industry 4.0 using industrial platforms. These are similar to social and commercial platform such as Amazon, Google, Facebook. These platforms are not limited to supply technologies but propose also a continuative relation with manufacturing firms including studies on their specific needs, technology updating, exchange of information and data, offer of services (big data, cloud computing, cybersecurity, etc.) on the base of the wide and diversified structure of the platform in what it has been called Industrial Internet. Industrial platforms are of course, significantly different from social and commercial platforms, built on instant reaction or gratification, as offers of technology and services of an industrial platform need solidity and reliability. A brief general description of any type of platform may be found at http://platformdesigntoolkit.com/toolkit. A platform may be seen as a system of concentric circles. At the center there are the owners, in our case the big companies organizing the platform. Close to the center there are the partners, subsidiary or consulting companies, that are in close and continuous relation with the owner to operate the platform. Externally we have the peer producers, firms, consultants, etc. that collaborate with the platform following the needs. More externally there are the peer consumers, customers of the platform technologies and services, in our case the manufacturing industry. Externally to the circle we have thestakeholders, entities that favorize the platform activity, for example in our case organizations promoting Industry 4.0. Although at the beginning industrial platforms have been considered by big companies, there are now examples of platforms planned by technological consulting firms and even proposed by start-up in offering new technologies.

Technological consulting firms

Although the existence of big industrial platforms, technological consulting firms would find their place in the ecosystem facing the multiplicity of needs existing in the Industry 4.0 environment. In fact, technological consulting firms have various possible strategies: major consulting firms may try to develop specialized platforms in concurrence with big platforms, or they may try the collaboration with a platform as peer producer or even as partner. Technological consulting firms may suffer of a situation of Red Queen Regime, and by rapid changes in available technologies in the implementation of their projects.

Universities and research laboratories

Universities and research laboratories can of course contribute to the offer of technology for Industry 4.0. Actually, in Italy there is some difficulties in the science to business process because of a prevalent cultural view of research, with a large activity in publications, but low generation of patents. On the other side university legislation and regulations are not very favorable to an entrepreneurial view of research, and that it is accompanied by a lack of human and financial resources in university offices of transfer of technology. In the case of Industry 4.0 it is interesting to consider the Italian governmental plan to support such transformation by improving relations between university and industry, in particularly SMEs. The plan is based on creation of Digital Innovation Hubs and Competence Centers. Digital Innovation Hubs are technological clusters generated by a bottom up process among industries, research centers, and acting as a strategic asset for growth and bridging industry, research and finance. The Competence Centers have the objective to intensify the relation between university and industry involving the best university poles and major private players. The governmental plan may be an important tool for implementation of Industry 4.0, however evolution of the ecosystem offering the enabling technologies, following the possible diffusion of industrial platforms, might change the innovative environment considered by the plan. In particular Competence Centers might become in competition with platforms. These last ones may offer a continuous innovation environment based on their large and flexible source of technologies, and that might be preferred to an activity of single projects of transfer of technology. That might lead to a situation in which business to business prevails on science to business relations. Actually, Competence Centers might have alternatives for example becoming peer producers for platforms, and Digital Hub Innovation operating as stakeholders. Another possibility for Competence Centers is to operate also as a platform, however they should have the necessary means and organizational flexibility. A last observation about Competence Centers is that their success will depend also on an active relation with industries by proposing new technologies, and not just to wait for industries bringing them their needs.

Start-up and their role in Industry 4.0

A start-up may play two types of role in the frame of Industry 4.0. In the first one it may develop new enabling technologies, and in a second one it may develop a manufacture with a full application of Industry 4.0, and also develop new products using IoT technologies. Start-up companies may have also some competitive advantage in respect to traditional manufacturing SMEs because they can leverage the advantage of starting without the legacy of an existing business and customer base, and thus can create a variety of presumably new business models. Although there is actually a great interest on start-up, their role in Industry 4.0 is not much considered despite their potentiality. A certain number of structures and promoting entities are active for start-up development. We have structures such as spaces for co-working, open labs for prototypes, incubators and scientific and technological parks., as well as entities supplying coaching and financial aids. However, little has been done about the promotion of the process of generation of start-up, typically resulting by a spin off from universities, research laboratories, industries and technological consulting firms. A positive action in generation of startup may be found in the activity of the association “La Storia nel Futuro” that organizes study tours in the Silicon Valley for Italian students and entrepreneurs. Between 2005 and 2017 this association has given the opportunity to make such tour to 314 university students generating a total of 20 start-up.

INDUSTRY 4.0 AND SMEs

The relation between Industry 4.0 and SMEs in industrial districts is presently still under study and here it is possible to present only some preliminary considerations. Implementation of Industry 4.0 in SMEs has some pre-existing difficulties of economic nature that are the low availability of capitals and the low production capacities limiting the return of investment done for implementation of Industry 4.0. That may bring to a minor implementation of enabling technologies resulting in a disadvantage in respect to concurrent medium or big firms that have more investment capacities. The various enabling technologies do not present the same difficulty of implementation in SMEs. Technologies such as collaborative robotic are easily acceptable, as well augmented reality, while digital manufacturing and especially digital twin may be less acceptable for their cost and radicality of the innovation. By consequence the use of general enabling technologies such as big data, cloud computing and cybersecurity might be quite limited. For the same reasons the development of new products using IoT technologies would be also difficult. Furthermore, the diffusion of Industry 4.0 in SMEs and industrial districts may be prevented by existence of a Red Queen regime and skepticism toward radical technologies. Ii might be present also technological intranality effects penalizing the introduction of new technologies as cited previously. Nevertheless, in the case of industrial districts it is possible to consider some solutions to the problems described previously. A first one is based on cooperation among SMEs with the same type of products about studies of implementation of Industry 4.0 reducing the costs for each partner. Such possibility has been exploited since many years for R&D projects in the case of Consorzio Ruvaris, composed by producers of tap and valves. In this case intranality effects may be avoided including also partnership of subcontracting companies. A more radical approach, but interesting for a study, is the idea to create a great manufacturing plant, operating in Industry 4.0, able to produce the various types of products of various firms. In this case the activity of the firms will be limited to innovation, design and commercialization, keeping advantages by a production in Industry 4.0 and the high production capacity of the plant.

General structure of an industrial platform in term of concentric circles

Owners: platform proprietary

Partners: firms with a closed and continuous cooperation with the platform

Peer Producers: firms with a cooperation with the platforms following the needs

Peer Consumers: firms connected with the platform and using its services and technologies

Stakeholders: entities favorizing the activity of the platform